If the cruciform or fixing screw is damaged there are a few installation points that should be checked. These will cause extra tension on the fleece making it harder for the motor to advance and can cause the cruciform to fail as designed.

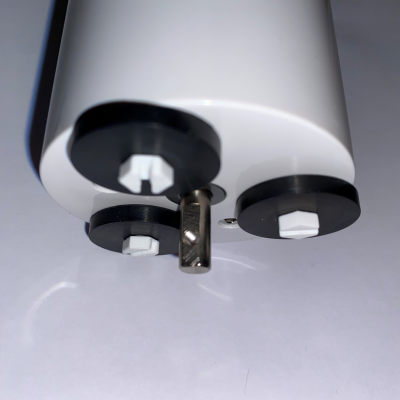

The dirty roll assembly needs to sit level on the unit.

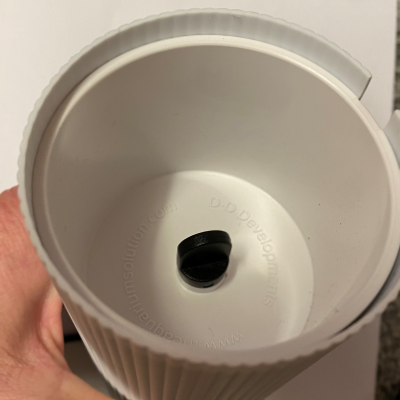

The mounting slot on the back plate of the ClariSea unit has an indicator line, the centre of the fixing screw on the dirty roll assembly should be positioned central to this line. The front of the dirty roll assembly should rest on the front skid plate. If this is not aligned properly the fleece will wander to the left or right and in some cases cause the dirty roll to form a bulge on one end.

For more information please click on the FAQ below,

https://www.theaquariumsolution.com/why-my-clarisea-forming-bulge-one-side-dirty-roll

The dirty roll should lay flat and not have a bulge in the middle.

If the dirty roll has a bulge in the middle then the guide plate may have developed a curve due to extra tension from the fleece or the nuts being tightened too much on the threaded rods. This would be specific to the SK5000 model due to the wider plates and fleece.

For more information please click on the FAQ below,

https://www.theaquariumsolution.com/how-do-i-stop-my-clarisea-sk5000-fleece-forming-ridge-centre-dirty-roll

The clean fleece needs to remain dry. Care must be taken not to position the unit in a way that the clean fleece can become wet from water splashing in the sump or made wet during maintenance. If the clean roll becomes wet it can deform and will no longer unroll as it needs to.

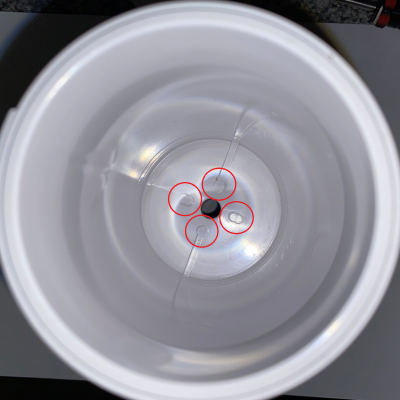

If the unit has been running for some time it is possible that the rollers that guide the fleece at the bottom of the unit have become dirty and are no longer allowing free movement. In this case the unit should be taken off and cleaned. Never use boiling or hot water to clean the unit or its components.

Certain versions of the ClariSea unit may have an extra strip of material attached to the top of the white filter plates. This must be positioned so that it is facing outwards away from the fleece. If it is not the fleece may not be able to move freely over it and there is a potential that water will be able to bypass the fleece unfiltered.