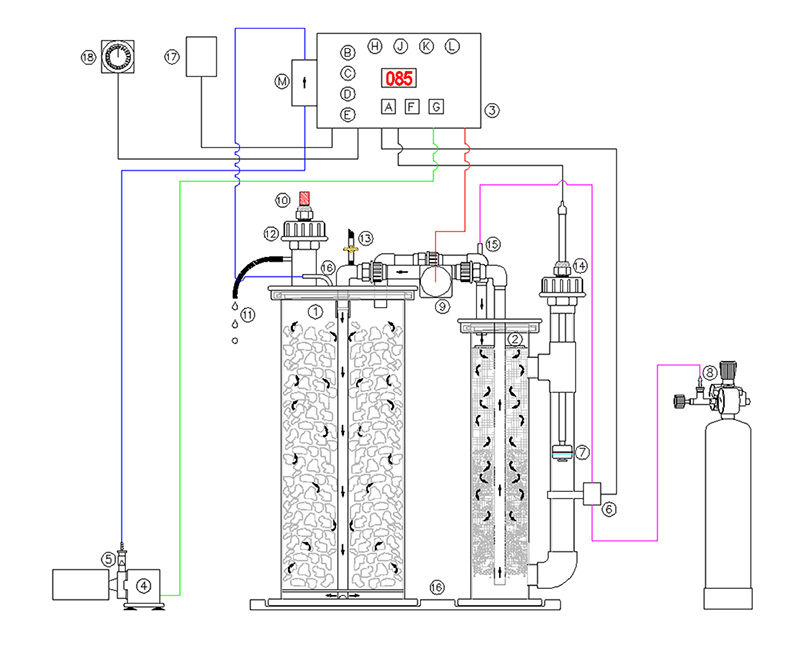

The innovative Twin-Tech reactor has several unique features providing simplicity of control but also relating to the way that the system feeds the reactor with water from the aquarium.

The smart controller on the Twin-Tech uses a built in flow meter to accurately measure the volume of water passing into the reactor, information it uses to control a standard DC feed pump. This feature allows the user to know exactly how much reactor effluent, in litres, is being added to the aquarium within each 24-hour period, which is shown on a large LCD display in the centre of the controller.

The water flow can be adjusted by the user between 10 and 350lt per day simply by pressing two up and down buttons on the panel.

The reactor as standard consists of the following items.

- Large media chamber.

- Smaller gas chamber with float switch.

- Controller with separate power supply unit.

- Recirculation pump and connections.

- Feed pump with suction filter.

- Low voltage solenoid valve.

- Hoses and non-return valves to connect the unit.

Not included

- CO2 bottle, CO2 regulator (important, 2 stage regulator is required) and CO2 hose.

- Calcium reactor media.