After cleaning the Aquabee pump as outlined at the link below it is most important that the impeller and grommets are reinstalled correctly for smooth trouble free operation. Although the link is specific to the skimmer pumps the basic cleaning schedule and maintenance also applies to the standard Aquabee pump installed on many Deltec products.

CLEANING THE MC/AP AQUABEE SKIMMER PUMP

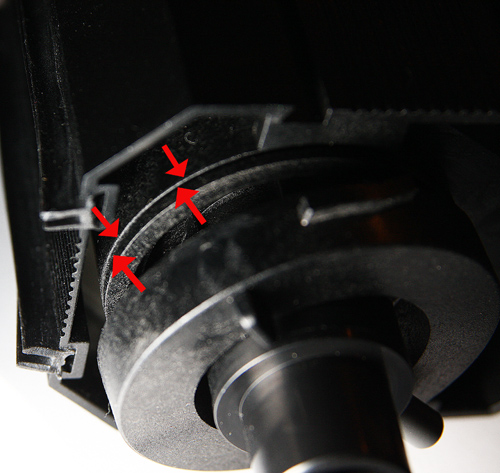

When replacing the grommets into the housings at both ends of the pump it is important that they are installed flush and don’t distort within the housing causing them to sit at a slight angle. This will cause the impeller shaft to catch or snag inside the grommet bearing as it spins(new style) or enter the grommet off centre(old style) which will cause the impeller to sit to one side of the impeller aperture and spin off centre or rub the inside of the pump.

If the old style grommets are tight when installing them a light smear of olive oil or silicone grease will aid installation and prevent the grommet from snagging within its housing and twisting. When installing the new style grommets with intergrated bearings it is essential to lubricate them as they may twist in the housing.Correctly installed Grommet

New style

Old Style

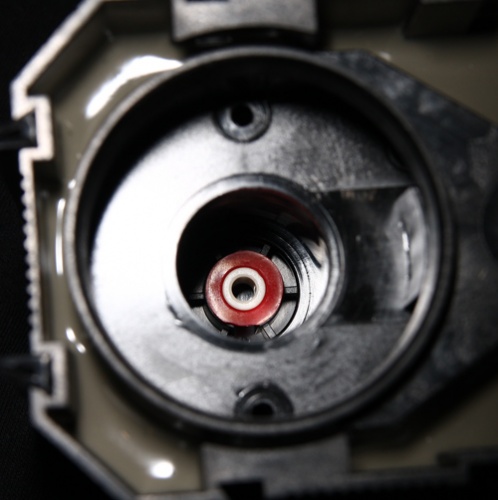

Bottom grommet (new style)

Impeller sitting correctly in the grommet (new style)

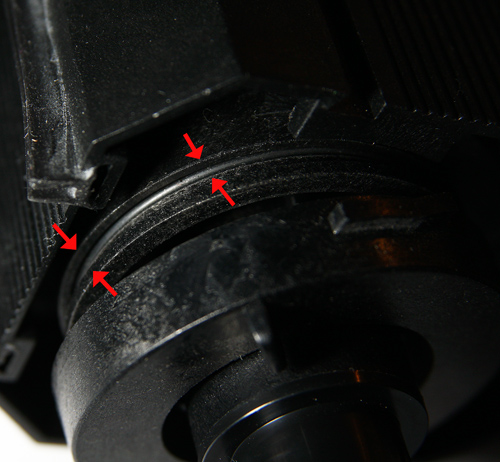

When installing the suction side do not use the bayonet on the suction side face plate to force the face plate into position. By doing this the o-ring around the faceplate may catch and cause the face plate to seat at an angle. This will cause the impeller shaft to sit at an angle within the grommet (old style) or bind in the grommet bearing (new style)

The suction plate should be pushed fully home by putting pressure on the end pipe work before the bayonet fitting is engaged. Again a light smear of olive oil or silicone grease on the face plate o-ring will help ease installation.

Faceplate before complete installation

note the gap that needs to be closed and the exposed o-ring.

Face plate fully home

If you find there is a gap between the faceplate on the opposite side remove the faceplate and push home again making sure the impeller shaft enters the grommet. Once the face plate is square to the pump with no gaps between them the bayonet can be locked into position