Occasionally it may be the case that foreign material makes its way into the valve, either from debris in the bottle valve, or from water entering the valve. This may either jam the inner piston open or closed depending on the nature of the obstruction.

Please follow the steps below. If the valve still doesn’t work afterwards, please feel free to contact your dealer for a replacement ensuring you also provide proof of purchase within the warranty period.

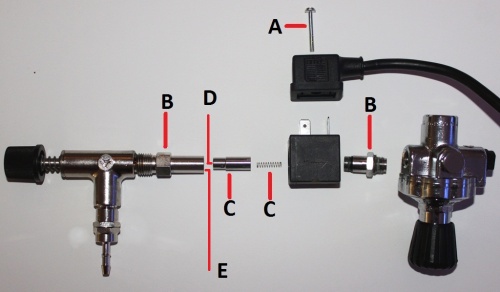

As per Image:

1. Using a screw driver remove screw (A) and pull off the electrical connector block to prevent damage to it.

2. Using two applicable spanners, split the unit by unscrewing the centre valve tube at points (B) (these two tubes screw into one another sandwiching the electo-magnet in place between them so they will need turning in opposite directions)

3. Remove the Piston and return spring. (C)

4. Clean the piston including the rubber end seal (D) and ensure the return spring travels freely in and out of the piston.

5. Inspect and clean inside the piston barrel (E) ensuring there are no particles of dust, debris, or corrosion.

6. Reassemble the unit in reverse order ensuring all joints are firm and tight to rule out any leaks.

7. connect and run the unit as per the original instructions.

Always use an inline non return valve between the solenoid/gauge assembly and the diffuser (fresh water) or reactor (salt water) to limit the chances of back siphoning to the solenoid which may cause corrosion and malfunction of the unit.